Welcome to Country Life Brewery

BREWING

Beer making dates back to 5,000 BC when yeast was discovered fermenting in a sugar-

Making beer can be broken down into two separate processes -

The two most common methods of malting are the traditional floor malting method, where grain is literally spread across the floor to germinate, and pneumatic malting, most common today, where the environment is strictly controlled inside tanks or drums. Maltsters can malt grains for a wide variety of different types of malt, each offering a different flavour and character.

Beer has four main ingredients -

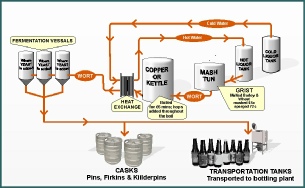

To brew beer, the brewer begins by weighing the appropriate amount of grain for his recipe. He then mills his malt in a malt mill which cracks his grain. In commercial operations, the milled malt drops into a grist case which has a valve at the bottom which allows the grain to drop through a chute into the mash tun. Usually homebrewers simply collect their milled grain in a clean container and dump it into their mash tun. The mash tun is a large vessel, usually made of copper or stainless steel, that has a screen-

Mash is a thin mixture of grains and hot water. Mashing is the process of heating grains mixed with water at controlled temperatures for designated periods of time to activate enzyme activity that converts starches to fermentable sugars. Converting starches to sugars is called saccharification. There are three common mashing methods. Infusion mashing is the simplest because it involves only one temperature throughout the mashing process. Step infusion mashing is basically infusion mashing with one or two temperature increases during mashing. And decoction mashing, most commonly used for lager style beers, is the most complex method because part of the mash is removed and boiled, then reintroduced.

Once mashing is completed, the brewer must separate the sugar-

The boil is a critical step in the brewing process because it is at this step that hops, the aromatic flowers of hop vines, are added. Hops impart aroma, flavour, and bitterness to beer, which balances the sweetness of the wort. To extract the bitter resins from hops they must be boiled, and usually hops are added at various stages of the boil to extract bitterness or impart aroma or flavour.

When the boil is completed, the hot wort is transferred to a heat exchanger or wort chiller which rapidly drops the temperature of the wort to about 80 degrees -

The main genus of yeast used by brewers is Saccharomyces, and the species used to make ales is a top fermenting strain called cerevisiae, while the species used to make lagers is a bottom fermenting strain called uvarum. The type of yeast used during fermentation determines whether a beer is an ale or a lager.

The yeast sets to work eating the malt sugar and expelling alcohol and carbon dioxide. This usually takes three to seven days and is referred to as primary fermentation. Homebrewers then rack or transfer the beer off of the yeast bed and into a secondary fermentation vessel, whereas commercial brewers drain the yeast that has collected out of the bottom of the tank.

The two most common methods of malting are the traditional floor malting method, where grain is literally spread across the floor to germinate, and pneumatic malting, most common today, where the environment is strictly controlled inside tanks or drums. Maltsters can malt grains for a wide variety of different types of malt, each offering a different flavour and character.

Beer has four main ingredients -

To brew beer, the brewer begins by weighing the appropriate amount of grain for his recipe. He then mills his malt in a malt mill which cracks his grain. In commercial operations, the milled malt drops into a grist case which has a valve at the bottom which allows the grain to drop through a chute into the mash tun. Usually homebrewers simply collect their milled grain in a clean container and dump it into their mash tun. The mash tun is a large vessel, usually made of copper or stainless steel, that has a screen-

Mash is a thin mixture of grains and hot water. Mashing is the process of heating grains mixed with water at controlled temperatures for designated periods of time to activate enzyme activity that converts starches to fermentable sugars. Converting starches to sugars is called saccharification. There are three common mashing methods. Infusion mashing is the simplest because it involves only one temperature throughout the mashing process. Step infusion mashing is basically infusion mashing with one or two temperature increases during mashing. And decoction mashing, most commonly used for lager style beers, is the most complex method because part of the mash is removed and boiled, then reintroduced.

Once mashing is completed, the brewer must separate the sugar-

The boil is a critical step in the brewing process because it is at this step that hops, the aromatic flowers of hop vines, are added. Hops impart aroma, flavour, and bitterness to beer, which balances the sweetness of the wort. To extract the bitter resins from hops they must be boiled, and usually hops are added at various stages of the boil to extract bitterness or impart aroma or flavour.

When the boil is completed, the hot wort is transferred to a heat exchanger or wort chiller which rapidly drops the temperature of the wort to about 80 degrees -

The main genus of yeast used by brewers is Saccharomyces, and the species used to make ales is a top fermenting strain called cerevisiae, while the species used to make lagers is a bottom fermenting strain called uvarum. The type of yeast used during fermentation determines whether a beer is an ale or a lager.

The yeast sets to work eating the malt sugar and expelling alcohol and carbon dioxide. This usually takes three to seven days and is referred to as primary fermentation. Homebrewers then rack or transfer the beer off of the yeast bed and into a secondary fermentation vessel, whereas commercial brewers drain the yeast that has collected out of the bottom of the tank.